In the chaotic world of asset management, keeping track of everything can feel like herding cats—impossible and slightly maddening. But fear not! An asset maintenance checklist is your trusty sidekick in this adventure. It’s like having a GPS for your equipment, guiding you through the twists and turns of maintenance tasks while ensuring nothing slips through the cracks.

Table of Contents

ToggleUnderstanding Asset Maintenance Checklists

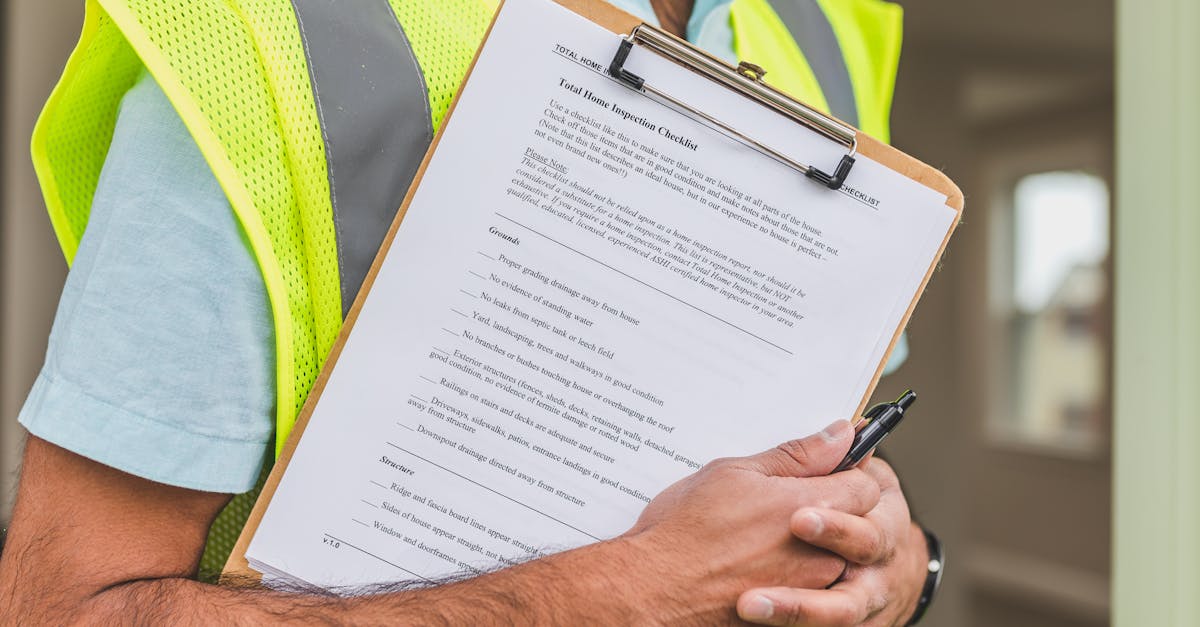

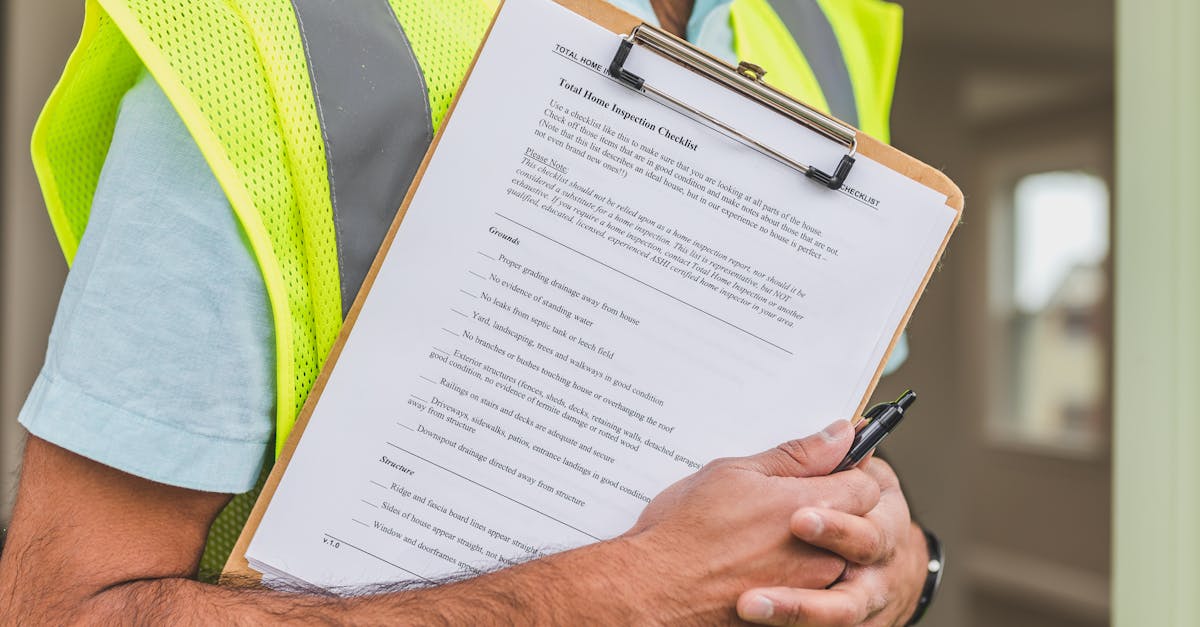

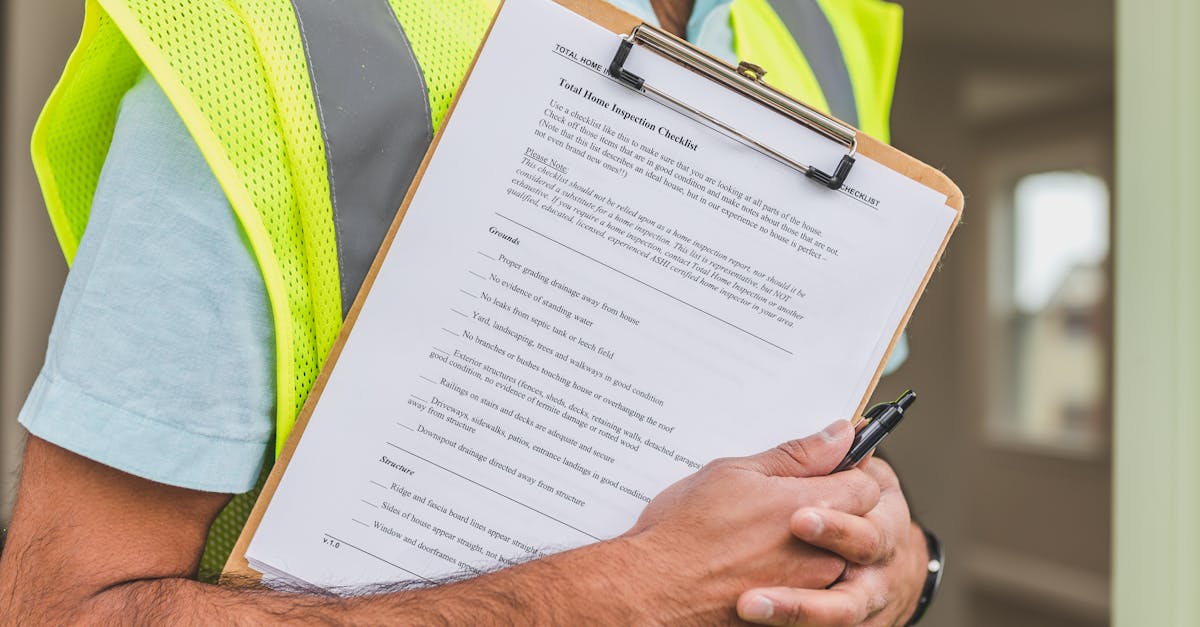

Asset maintenance checklists streamline the maintenance process, ensuring efficiency and effectiveness in managing equipment. A well-constructed checklist serves as a reliable guide that helps organizations prioritize their maintenance activities.

Importance of Asset Maintenance

Effective asset maintenance prevents costly downtimes and extends the lifespan of equipment. Routine checks can identify potential issues before they escalate, leading to fewer disruptions in operations. Asset maintenance also enhances safety standards, reducing risk for employees. Regular investment in maintenance pays dividends through increased productivity and performance. Organizations that emphasize asset maintenance often experience lower operational costs, making it crucial for long-term success.

Key Components of a Checklist

An asset maintenance checklist includes several essential elements that contribute to its effectiveness. First, it should outline specific tasks required for each asset, such as inspections, cleaning, and repairs. Furthermore, the checklist must include frequency of tasks to ensure timely completion. Each task should have a designated responsible person to promote accountability. Checklists should incorporate documentation space for tracking maintenance history. Lastly, prioritization indicators help focus on critical tasks that require immediate attention, enhancing overall asset management.

Types of Asset Maintenance Checklists

Asset maintenance checklists come in various types, each serving a unique purpose in managing equipment effectively. Understanding these types can help organizations structure their maintenance strategies more efficiently.

Preventive Maintenance Checklists

Preventive maintenance checklists focus on routine tasks performed to reduce the likelihood of equipment failures. Each checklist item includes essential actions such as lubrication, cleaning, and inspections. Frequency of tasks can vary from daily to annually, depending on the equipment’s usage and manufacturer guidelines. Responsible personnel must execute these tasks consistently to ensure optimal performance. Organizations can prioritize critical machinery to prevent costly downtimes.

Corrective Maintenance Checklists

Corrective maintenance checklists address issues after a failure occurs. These checklists guide technicians through corrective actions required for repairs. Items typically involve specific steps for diagnosing problems and executing necessary fixes. Task frequencies vary based on equipment failure history, making it essential to document previous issues accurately. Clear responsibilities for technicians help ensure rapid response times. Identifying high-priority assets allows focused action, minimizing operational disruptions.

Predictive Maintenance Checklists

Predictive maintenance checklists utilize data and analytics to foresee potential equipment failures. These checklists incorporate metrics such as vibration analysis, thermal imaging, and oil analysis. They guide technicians in monitoring equipment conditions and executing tasks based on indicators rather than set schedules. Task prioritization relies on actual conditions rather than assumed timelines. Utilizing predictive strategies enhances equipment reliability and minimizes unexpected downtimes. Establishing a pattern of continuous monitoring helps organizations maximize their asset lifespan.

Creating an Effective Asset Maintenance Checklist

An effective asset maintenance checklist plays a crucial role in managing equipment efficiently. Several key components contribute to the development of a thorough checklist.

Identifying Assets

Begin by cataloging all assets that require maintenance. Each asset needs a clear identification reference for easy tracking. Include both major equipment and smaller tools in this inventory. Classifying assets by type or function simplifies the process of assigning maintenance tasks. This organization enhances visibility for asset managers, ensuring no item is overlooked during maintenance routines.

Defining Maintenance Tasks

Outline specific maintenance tasks for each identified asset. Regular checks, lubrication, and safety inspections form the foundation of these tasks. Assigning detailed descriptions for each task boosts accountability among team members responsible for execution. It’s essential to keep tasks relevant to the asset’s operational requirements and manufacturer’s guidelines. Updates should occur as necessary to adapt to changes in equipment usage or performance.

Setting Frequencies and Responsibilities

Task frequency directly impacts overall equipment reliability and performance. Establishing a schedule for both routine and non-routine tasks ensures timely maintenance interventions. Assign clear responsibilities to team members to foster efficiency and ownership of tasks. Highlighting critical tasks with heightened frequencies supports proactive maintenance and prevents unexpected equipment downtime. Documenting these details within the checklist facilitates better tracking of compliance and outcomes.

Implementing Your Asset Maintenance Checklist

Implementing an asset maintenance checklist requires systematic training and effective use of technology. These elements ensure a smooth maintenance process and facilitate adherence to best practices.

Training Your Team

Training employees on how to use the asset maintenance checklist fosters a culture of accountability. Regular training sessions reinforce the importance of specific tasks, frequencies, and responsibilities. Employees receive guidance on identifying maintenance tasks aligned with operational needs. By understanding the checklist’s role in preventing failures, teams enhance compliance and performance. Clear communication promotes better teamwork and encourages employees to take ownership of their responsibilities.

Utilizing Technology for Checklists

Technology plays a crucial role in streamlining asset maintenance checklists. Digital tools offer platforms for creating, managing, and updating checklists efficiently. Automated reminders for upcoming tasks help ensure nothing is overlooked. Integration with data analytics can enhance predictive maintenance, allowing for real-time monitoring of asset conditions. Using mobile applications enables technicians to access checklists on-site, improving responsiveness to issues. Organizations that leverage technology not only boost efficiency but also promote a proactive maintenance culture.

Conclusion

An asset maintenance checklist is essential for organizations aiming to optimize their equipment management. By implementing a structured approach to maintenance tasks, companies can significantly reduce downtime and enhance productivity. The right checklist not only prioritizes critical tasks but also fosters accountability among team members.

Training employees on effective checklist usage and leveraging technology can further streamline the maintenance process. This proactive strategy leads to improved equipment reliability and longevity. Ultimately, a well-maintained asset base contributes to a safer work environment and lower operational costs. Embracing these practices equips organizations to navigate the complexities of asset management with confidence.